PROCESS

Every Field Report project starts with a conversation. We listen closely, gather insights, and draw inspiration from your goals and the character of the site. From these early influences, our team develops architecture that feels both personal and enduring — work that carries meaning, reflects its setting, and is executed with the rigor needed to meet budget, permitting, and construction requirements.

01. DISCOVERY & CONSULATION

We begin by listening: interviews with owners and stakeholders, an on-site visit when possible, and a focused review of existing documentation. Discovery is where we translate aspirations into a practical brief. We analyze site opportunities and constraints (views, topography, access, microclimate), confirm zoning and code drivers, and capture technical inputs such as survey, soils, and utility context. Early budget conversations and a high-level schedule allow us to align design ambition with reality from the outset.

We also use this phase to surface performance goals — sustainability targets, energy/code priorities, and any accessibility or phasing requirements — so these priorities are embedded in the design rather than retrofitted later. By the end of discovery we deliver a concise project brief that becomes the north star for all future decisions.

Key outcomes

Project brief and prioritized goals

Site analysis summary (constraints, opportunities, circulation)

Preliminary budget framework and high-level schedule

Required documentation checklist (surveys, reports, permits)

Early sustainability & code considerations

STEP 2. CONCEPT DESIGN

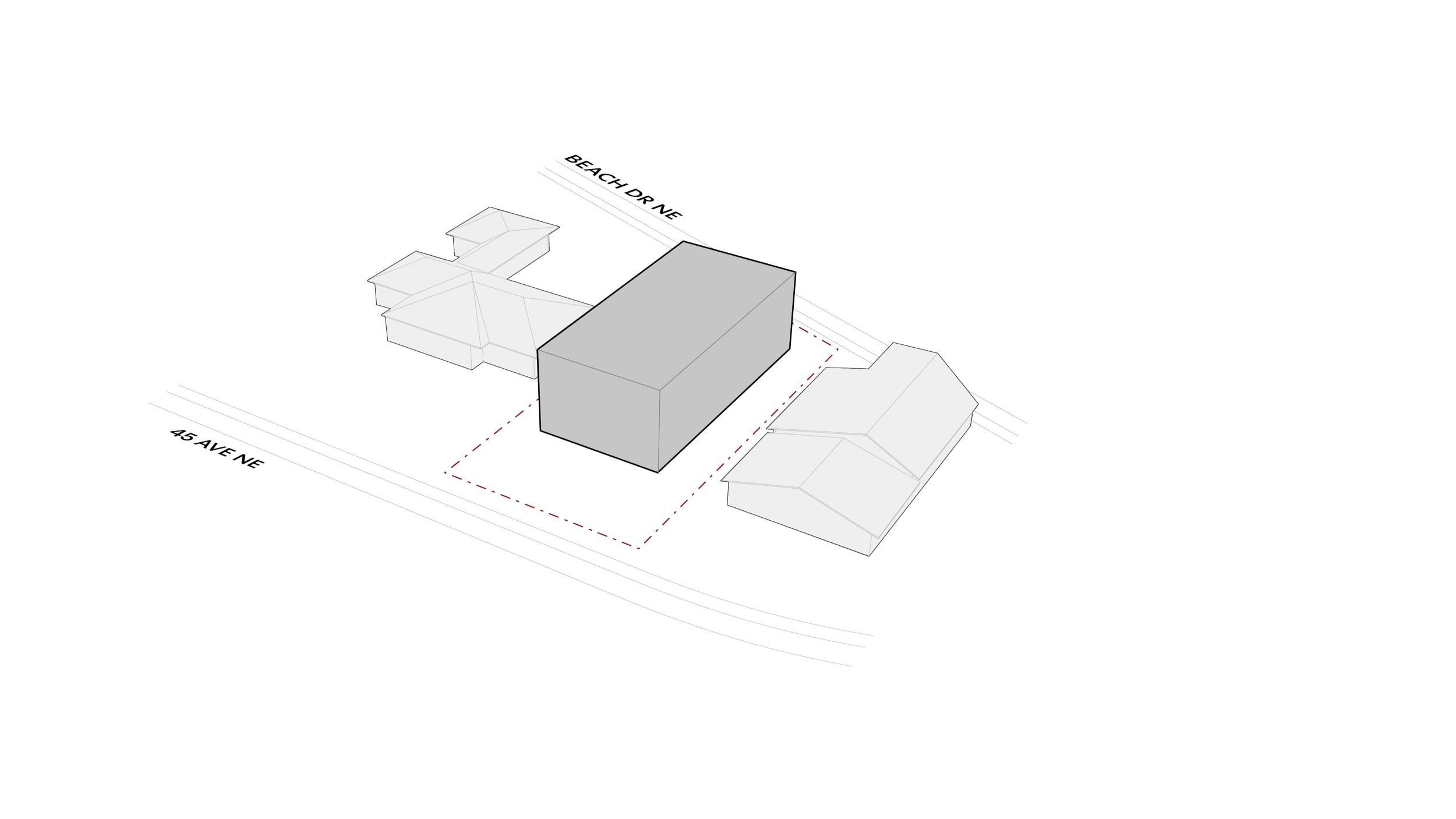

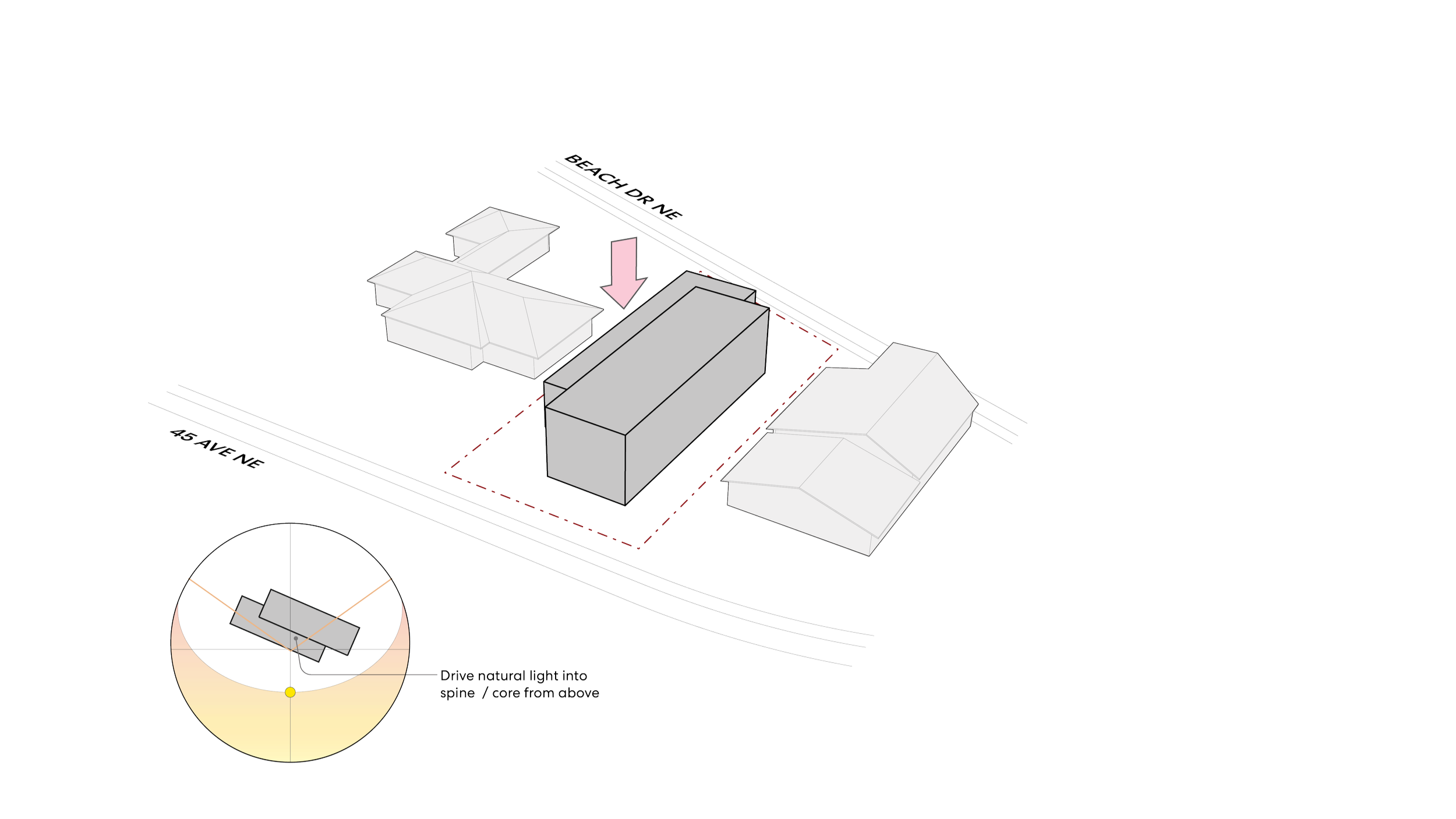

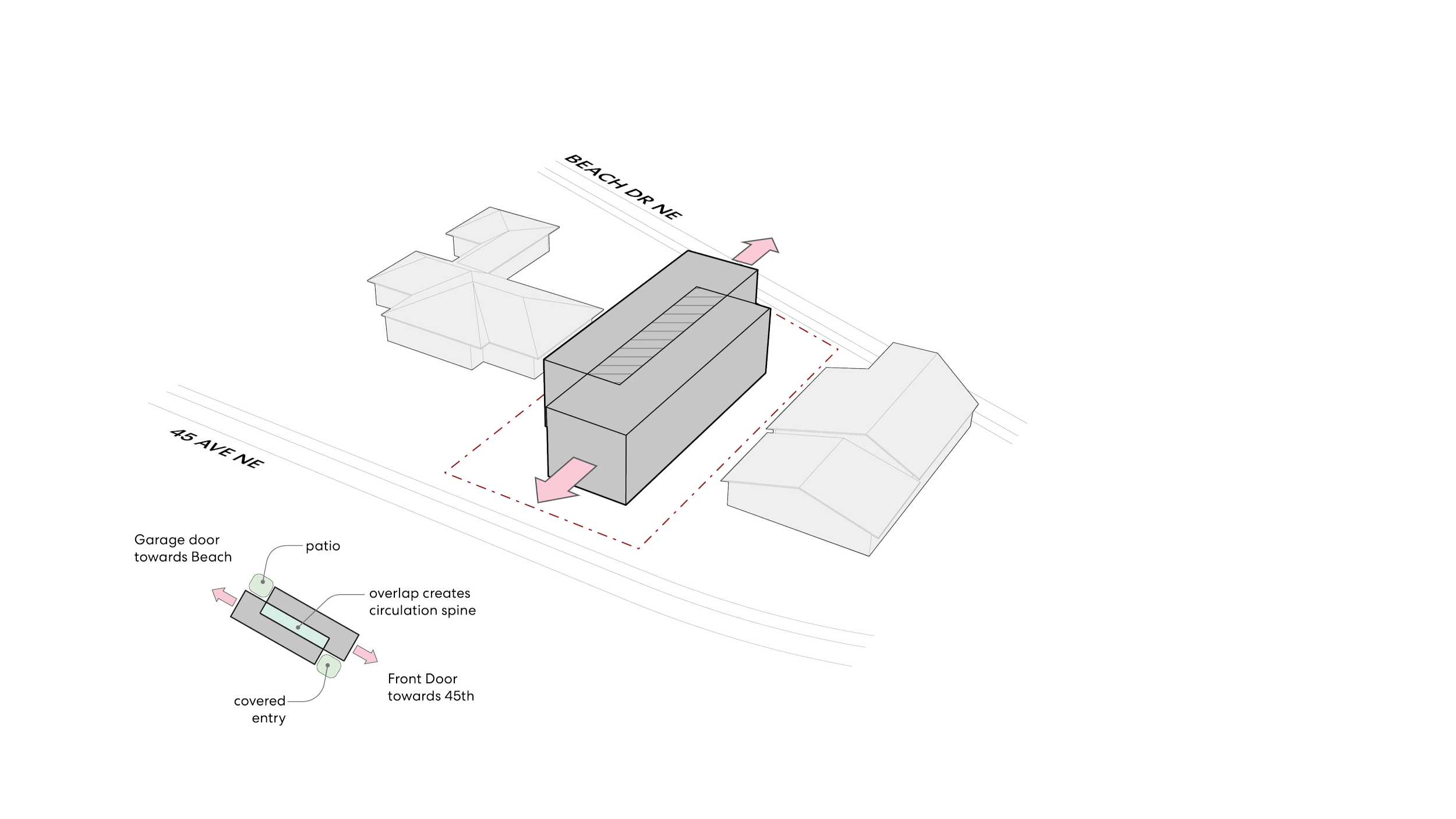

Concept design is an exploratory phase focused on big moves: siting, massing, plan organization, and how the building will sit in its landscape or neighborhood. We sketch multiple schematic options — plan diagrams, massing studies, and quick 3D views — to test light, orientation, privacy, and access. At this stage we balance aesthetics, program flow, and cost: rough cost benchmarks and contractor input are used to steer design choices and reduce costly revisions later.

We make decisions about the project’s spatial hierarchy (public vs. private zones), primary materials, and key architectural gestures. We also create visual reference boards and precedent studies to ensure we and the client share the same design intent. Client feedback is captured in structured review sessions so the design direction is confirmed before we advance.

Key outcomes

Multiple concept options and preferred direction

Massing and program diagrams, early 3D visuals

Preliminary materials and precedent boards

Initial cost benchmarking and schedule implications

Documented client feedback and confirmed design direction

STEP 3. SCHEMATIC DESIGN

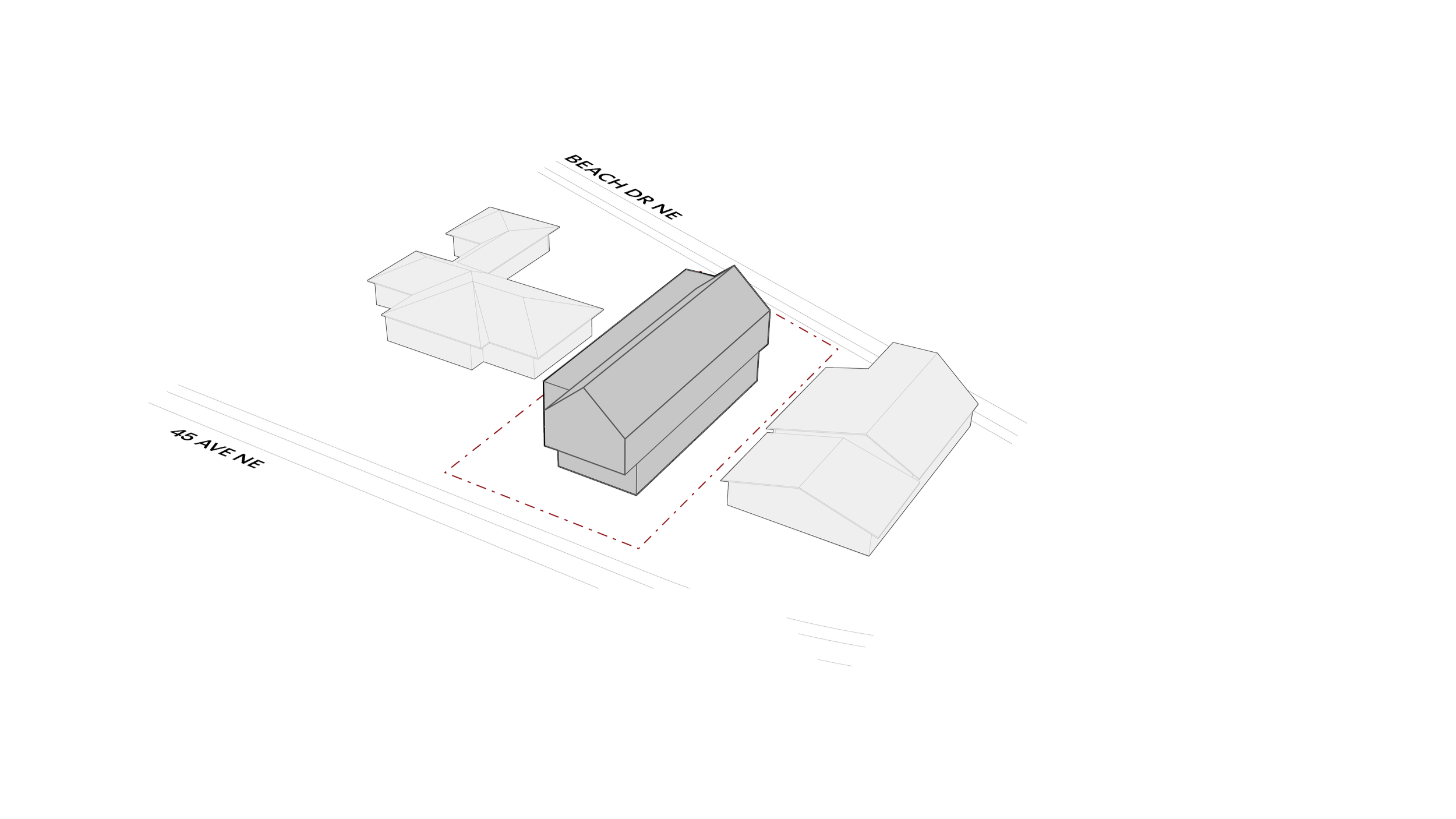

Once we’ve agreed on the concept, schematic design expands that idea into a coherent scheme with greater technical clarity. Floor plans, roof plans, exterior elevations, and scaled sections are developed to test spatial adjacencies, structural logic, and daylighting. We deepen consultant coordination (structural, civil, geotech, MEP) at a high level so important systems are integrated early and avoid late surprises.

We also begin selecting assemblies and material families (cladding strategies, window typologies, roof systems) and test those choices for durability and local suitability — critical in the varied Pacific Northwest climates we build for. At this phase we run basic performance checks (solar orientation, basic energy strategies, stormwater approach for site work) and produce more persuasive visualizations to help clients, lenders, or review boards understand the design intent.

Key outcomes

Coordinated schematic plans, sections, and elevations

3D massing and perspective views for review & approvals

Initial systems and assembly strategy (structure, envelope, MEP principles)

Material palettes and preliminary fixture/finish direction

Schematic design package for budgeting, stakeholder review, or preliminary permit submittal

STEP 4. DESIGN DEVELOPMENT

Design development is where the architecture is resolved into specific, coordinated systems. We finalize plan layouts, refine sections and wall assemblies, and lock down primary materials, fenestration systems, and critical details. Close coordination with structural and MEP engineers ensures that structural grids, mechanical routes, and service spaces are resolved without compromising the design intent.

We prepare outline specifications that define performance expectations for major systems and finishes, and we assemble sample boards for client approval. This phase commonly includes utility coordination, accessibility review, and more detailed cost validation so the team can identify value choices or necessary scope adjustments prior to documentation.

Key outcomes

Refined plans, sections, elevations, and key details

Outline specification and finish schedule

Integrated consultant drawings and coordination notes

Material and mock-up recommendations

Updated budget and implementation strategy

STEP 5. PERMITTING

Permitting is often a multi-step process: preparing code-compliant permit drawings, compiling the required documentation, and shepherding the package through the jurisdictional review. We assemble a permit set that emphasizes clarity — plan notes, egress, energy compliance reports, and consultant attachments — and we proactively manage review comments to minimize cycles.

Where projects involve conditional use, shoreline, design review, or environmental considerations (common for waterfront or winery sites), we develop a permitting strategy early in the project and coordinate with consultants and local officials as needed. Our goal is to secure the approvals necessary for construction without compromising the design.

Key outcomes

Permit drawing package and supporting documents

Energy/code compliance documentation

Coordinated consultant submittals (structural, civil, MEP, landscape)

Response log for agency comments and revisions

Issued permit and permit conditions summary

*Not quite this long, but sometimes it can feel that way & that’s where we come in - we’re experts at navigating the complexities of entitlement and bringing clarity to an unclear process.

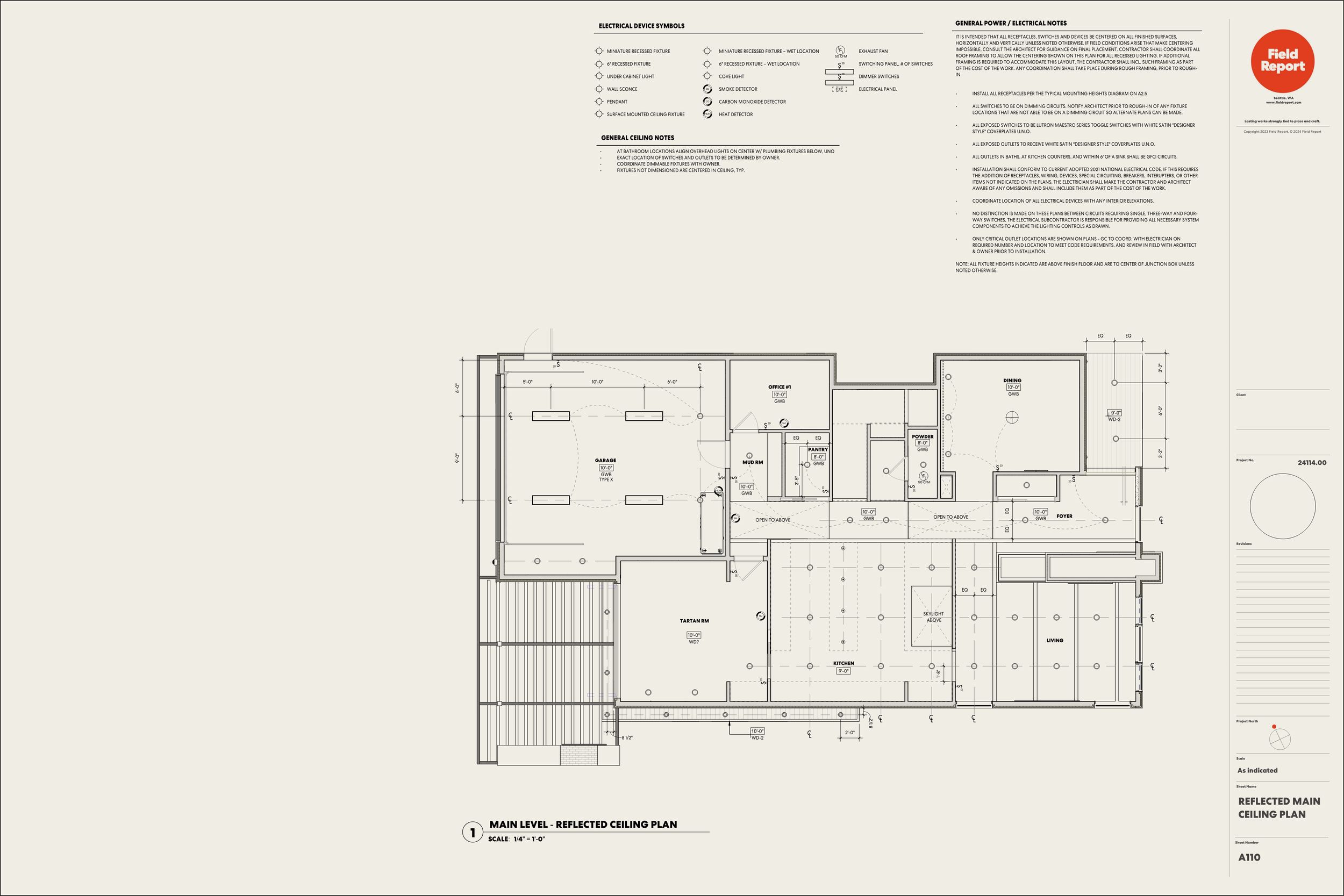

STEP 6. CONSTRUCTION DOCUMENTS

Construction documents translate the design into the precise instructions a contractor needs to build. We produce a fully coordinated set of drawings — site plan, floor plans, elevations, wall sections, typical details, schedules — together with a complete specifications manual that clarifies material, product, and workmanship expectations. We use robust QA/QC workflows (drawing reviews, clash checks with consultants, and coordinated sheet notes) to reduce omissions that cause delays in the field.

We can provide Revit/BIM export where required, annotated details for unique assemblies, and clear finish schedules to assist accurate bidding. During this phase we also support bidding by preparing addenda as questions arise and helping evaluate contractor proposals against the project goals.

Key outcomes

Full construction document set (plans, sections, details, schedules)

Project manual / specifications and finish schedules

Coordination-verified drawings for contractor pricing

Bid support and addenda management

Long-lead item recommendations and procurement guidance

STEP 7. CONSTRUCTION ADMINISTRATION

During construction we remain an active partner. We observe construction progress through site visits, review shop drawings and submittals, respond to RFIs, and help resolve unforeseen field conditions. Our focus is to maintain design intent while supporting efficient construction workflows. We document decisions, track changes, and assist with change orders when scope or conditions require adjustments.

As the project nears completion we lead punchlists, verify systems, and coordinate final inspections. We deliver closeout materials — record drawings (as-builts), warranty information, and maintenance notes — and can arrange a post-occupancy review to confirm systems are performing and to identify any modifications that will improve long-term performance.

Key outcomes

Regular site observation reports and RFI management

Submittal and shop drawing review

Punchlist, inspections, and final walk-through

Closeout package and record drawings

Optional post-occupancy evaluation and follow-up